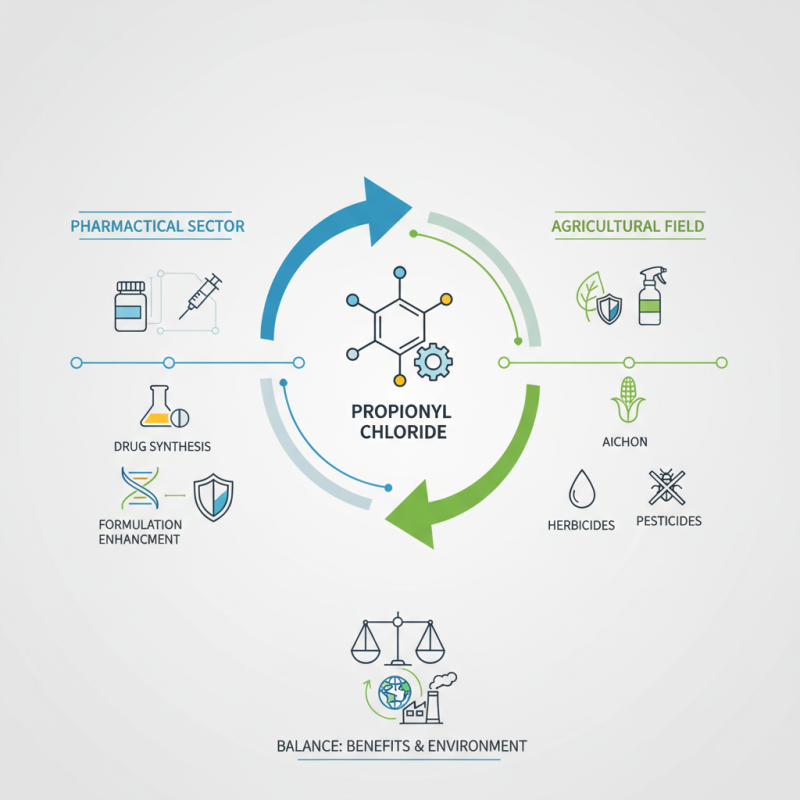

Propionyl Chloride is a versatile chemical compound used in various industries. Its applications span from pharmaceuticals to agriculture. This compound plays a crucial role in the synthesis of different products. Many industries rely on Propionyl Chloride for its effectiveness.

In the pharmaceutical sector, Propionyl Chloride serves as a key intermediate. It helps in producing important drugs. This compound enhances the properties of various formulations. This is essential for drug manufacturers aiming for quality and efficacy.

The agricultural field also benefits from Propionyl Chloride. It is used in producing herbicides and pesticides. These products help farmers protect crops. However, the use of chemicals isn’t without concerns. Industries must balance benefits and environmental impacts. Understanding the best uses of Propionyl Chloride is vital for responsible application and innovation.

Propionyl chloride is an important chemical in organic synthesis. It has a clear, colorless appearance and a pungent odor. This compound is highly reactive, particularly with water and alcohols. When exposed to moisture, propionyl chloride can hydrolyze quickly, releasing hydrochloric acid. This characteristic makes handling and storage crucial for safety and stability.

Tips: Always use appropriate protective equipment when working with propionyl chloride. Avoid contact with skin and eyes. Ensure a well-ventilated area to minimize inhalation risks.

In the lab, propionyl chloride is often used to create esters and amides. These derivatives play essential roles in various applications, including pharmaceuticals and agrochemicals. Its reactivity can be an advantage, but it can also lead to unwanted by-products if not controlled properly. Experimentation requires caution.

Tips: Start with small-scale reactions. Monitor conditions closely to prevent runaway reactions. Keep a detailed log of observations to learn from mistakes.

Propionyl chloride is a versatile reagent in organic synthesis. It plays a significant role in creating esters and amides. This compound can react with alcohols and amines, facilitating the formation of various derivatives. Its reactivity allows chemists to expand their synthetic pathways.

In industrial settings, propionyl chloride is used to manufacture pharmaceuticals and agrochemicals. The compound acts as an acylating agent. This aids in modifying functional groups in larger molecules. The efficiency of propionyl chloride shortens the synthesis time, yet it requires careful handling. Safety precautions are crucial due to its reactive nature.

Some challenges arise with its use. Byproducts may form during reactions, complicating purification processes. This can lead to inefficiencies in production. It's essential to monitor reaction conditions closely. The balance between efficiency and safety must always be maintained to ensure successful outcomes in propionyl chloride applications.

Propionyl chloride is gaining attention in the pharmaceutical industry for its versatility. This chemical compound acts as an acylating agent in various synthetic reactions. Its ability to enhance drug formulations is crucial. Propionyl chloride can improve solubility and bioavailability, making medicines more effective. The unique structure allows for better interaction with biological systems.

Another significant advantage is its role in creating propionyl derivatives. These derivatives often exhibit improved pharmacological properties. In some cases, they can be safer alternatives to existing compounds. However, the handling of propionyl chloride should be approached with caution. Its toxic properties necessitate proper safety measures during synthesis and application. Not all methods work seamlessly, and reactions can sometimes yield unexpected results.

Also, while exploring its benefits, researchers must address potential side effects. It's essential to assess the long-term impacts of using propionyl derivatives. The pursuit of innovation in pharmaceuticals is ongoing. Balancing safety and efficacy is a continuous journey in drug development, and each step requires careful consideration.

Propionyl Chloride is a vital chemical in various industries. Its handling requires strict safety measures due to its reactive nature. This chemical can cause severe health risks, such as respiratory issues and skin irritation. Exposure may lead to chemical burns, highlighting the need for caution.

Appropriate personal protective equipment (PPE) is essential when handling Propionyl Chloride. Goggles, gloves, and respiratory gear should be standard. According to industry reports, incidents involving chemical exposure are often linked to inadequate safety protocols. Regular training on proper handling techniques can mitigate these risks significantly.

Storage is equally critical. Propionyl Chloride should be stored in a cool, dry location. Containers must be sealed tightly to prevent leaks. Spills can cause hazardous situations, making spill control kits necessary in all handling areas. An estimated 30% of workplace incidents stem from improper storage practices. Awareness and adherence to safety guidelines can reduce such occurrences.

The future of propionyl chloride in industry is promising. As a versatile chemical, it plays important roles in various sectors. Growth is expected in pharmaceuticals, agrochemicals, and polymers. Increasing demand for efficient synthesis pathways drives this interest. Companies are exploring its potential for producing key intermediates.

One exciting area is its role in drug development. Researchers are focused on leveraging propionyl chloride to improve active pharmaceutical ingredients. Its effectiveness may lead to more sustainable processes. However, challenges exist in scaling production efficiently. Some facilities struggle to maintain safety standards while optimizing output.

Another trend is the shift towards eco-friendly applications. Industries are under pressure to reduce their environmental footprint. Using propionyl chloride in biodegradable polymers could be a game-changer. Yet, the transition requires reevaluation of existing methods. Innovations must prioritize both efficiency and sustainability, prompting ongoing discussions among stakeholders.